Tipping station/vibration screen/vacuum conveyor/ribbon mixer/screw conveyor/hopper

The first dust free bag dumping station/tipping station would keep your workshop clean while you pour raw material out from bags,especially for powder material.

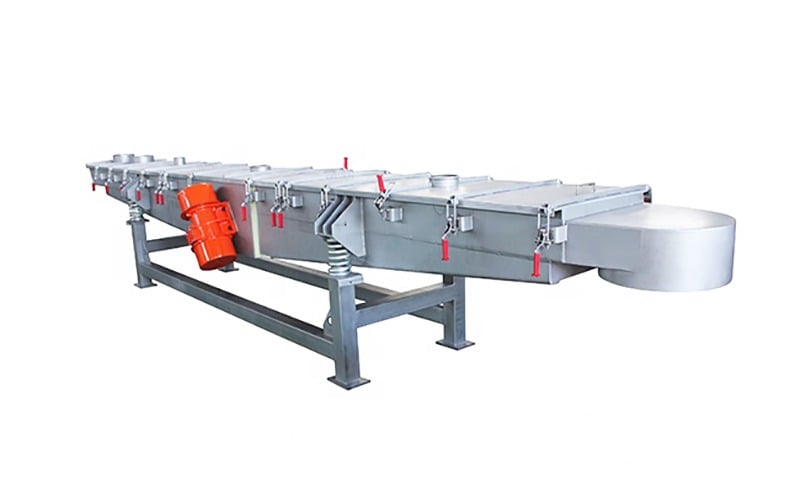

Most of raw materials would fall on the follow vibrating screener,the fine powder like dust,would be sucked by the up fan and filtered by the filter inside.

If you need sieve your raw material,to remove big particle size or remove powder from your granules,you can add this vibrating sieve under the station just like us.For this vibrating sieve,the sieve mesh is customized,so it could get the desired products.

The next vacuum conveyor could convey the products to the point you want in your production process,it could convey to a silo,a mixer,or other machine you want.

We add a mixer here,because our customer need mixer different products together.For this ribbon mixer,we have different models,from 50L to 5000L,this could have different capacities.

The next vacuum conveyor would convey the mixed product to a screw conveyor to make sure the discharging evenly.Finall the hopper under the screw conveyor would connected to other machines.