Combining grinding power with dust management, the universal pulverizer assembly with dust collector is a must for industries prioritizing cleanliness. It’s suited for pharmaceuticals, food, and chemicals, reducing hazards while delivering fine powders. This piece covers its mechanics, perks, and market shifts.

Mechanics Explained

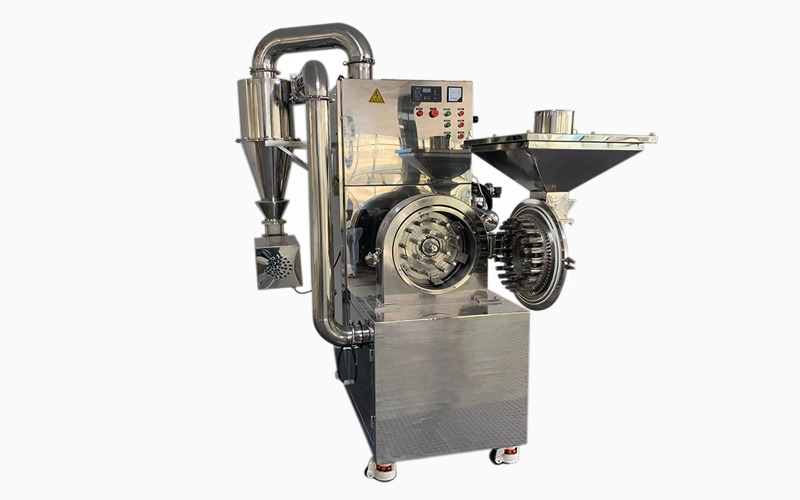

The pulverizer uses hammers to grind, while the dust collector—linked by vents—uses suction to capture particles in filters. Air is purified, and dust bagged. Controls adjust grind and extraction.

This setup ensures safe grinding, with options for cyclone or pulse-jet collectors.

Combined Benefits

Perks include:

Safety Enhancement: Captures dust, protecting workers.

Efficiency Boost: Continuous operation without stops for cleaning.

Quality Maintenance: Keeps materials pure.

Space Savings: Integrated design fits compact areas.

Cost Reduction: Less waste and maintenance.

A food factory grinding flour might achieve cleaner air and better output.

Industry Roles

Used in:

Pharma: Sterile drug grinding.

Food: Additive pulverizing.

Chemicals: Safe powder handling.

Cosmetics: Fine ingredient preparation.

In cosmetics, it ensures dust-free bases for products.

Selection Guidance

Consider material, air flow, and filter type. Choose user-friendly models for quick maintenance.

Trends Ahead

Pulverizer with dust collector trends feature sensor-based monitoring and sustainable filters, aligning with eco-standards.

This assembly combines safety and efficiency for grinding. Consult specialists for customization.