High-precision grinding is vital for industries requiring ultra-fine powders. Ultra fine pulverizers deliver this through innovative techniques, supporting pharmaceuticals, cosmetics, and more. This overview offers insights into their function, value, and trends, helping you assess their potential for your business.

Function Insights

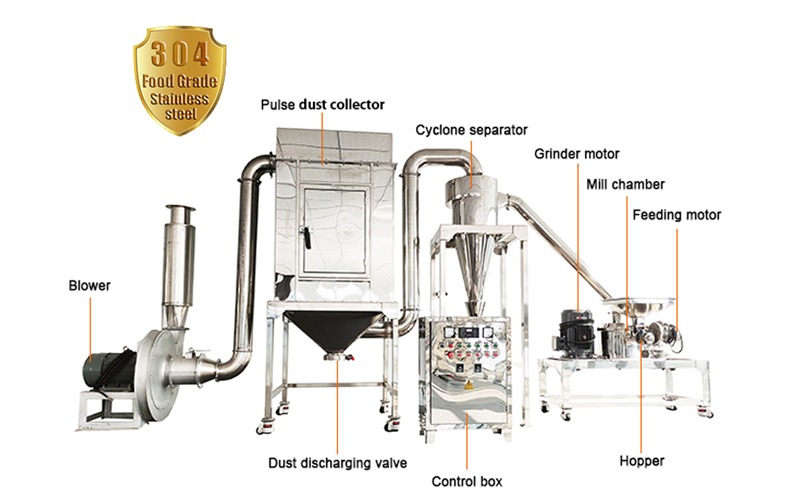

An ultra fine pulverizer utilizes air jets or mechanical forces to reduce particles to microns. Jet types use compressed air for collision-based grinding, while mechanical ones employ rotors. Integrated classifiers ensure precise size control.

This method maintains material integrity, avoiding heat or contamination issues.

Value Proposition

Insights show:

Precision Achievement: Delivers sub-micron accuracy for superior products.

Sensitive Material Care: Prevents degradation of heat-labile substances.

Operational Speed: High rates for efficient production.

Space Economy: Compact for easy integration.

Purity Maintenance: Closed-loop designs reduce impurities.

In cosmetics, it creates silky powders for foundations, enhancing user experience.

Implementation Areas

They’re implemented in:

Chemicals: Grinding pigments for paints.

Food: Producing super-fine additives.

Pharma: Creating dispersible drug forms.

Advanced Materials: Preparing powders for 3D printing.

In advanced materials, it enables nano-scale precision for tech applications.

Selection Guidance

Focus on grinding method, capacity, and material compatibility. Prioritize user-friendly features.

Trend Highlights

High-precision grinding is seeing sensor integration for monitoring and low-energy models for sustainability.

Ultra fine pulverizers offer high-precision grinding insights, driving innovation. Explore with a specialist for tailored solutions.