Helical blending technology is advancing to meet diverse needs. Ribbon mixers innovate this with efficient designs for uniform mixes. For B2B in pharma or food, this equipment can enhance precision. We’ll cover its function, benefits, and trends.

Function Overview

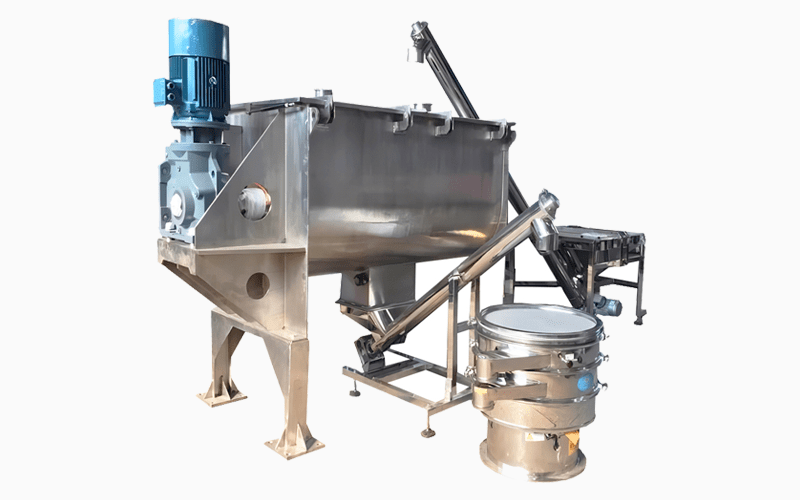

A ribbon mixer uses helical ribbons in a trough for blending. Rotation creates multi-directional flow, mixing materials thoroughly. It’s batch-based, with easy load/unload.

This innovation provides fast, even mixes for various viscosities.

Benefits Highlighted

Benefits feature:

Precision Mixing: No unmixed pockets for reliable results.

Scale Options: From pilot to production sizes.

Gentle Action: Low impact for fragile materials.

Clean Design: Quick disassembly for sanitation.

Savings Potential: Efficient energy use lowers costs.

In chemicals, it blends resins evenly, improving product performance.

Usage Highlights

Usage in:

Pharma: API blending.

Food: Dough preparation.

Agriculture: Fertilizer mixing.

Cosmetics: Cream compounding.

In agriculture, it ensures nutrient distribution.

Picking Insights

Focus on ribbon type, trough material, and controls. Select for your mix characteristics.

Trend Insights

Helical blending includes variable speed drives and sustainable materials, addressing eco demands.

Ribbon mixers innovate helical blending, driving quality. Discuss with suppliers for custom solutions.