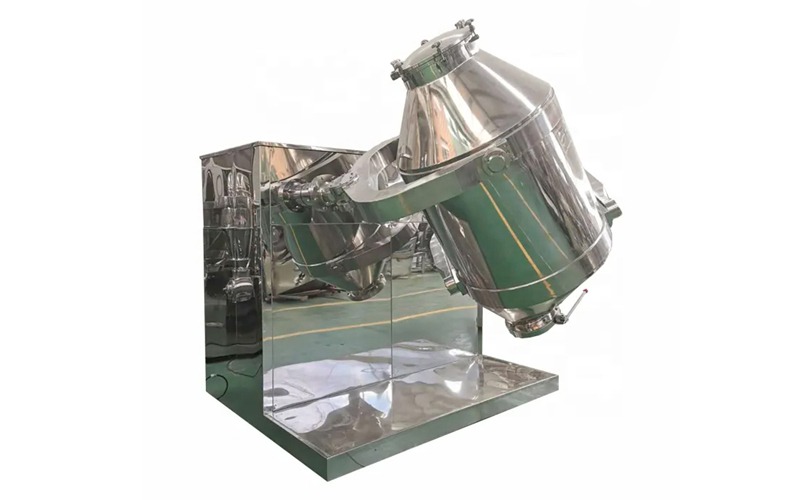

Innovation doesn’t stop in manufacturing, and after 40 years in the game at our factory, I’ve got a front-row seat to the latest in mixing tech. Three-dimensional mixers have come a long way, with new features making them even more indispensable for B2B operations. If you’re looking to stay ahead, here’s a rundown of cutting-edge developments and how they can amp up your processes.

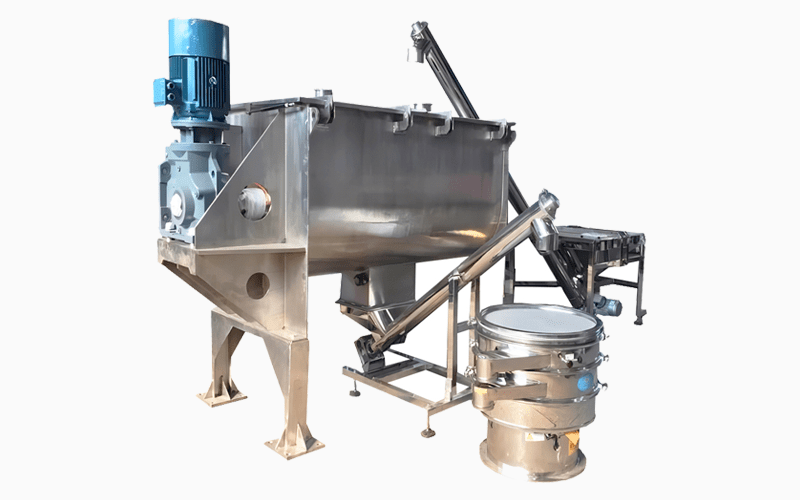

First up: smart controls. Modern 3D mixers now integrate PLC systems with touch-screen interfaces, allowing recipe storage and automated cycles. This cuts human error—think pre-set timers for exact mixing durations. We’ve implemented these in our lineup, helping a food client achieve consistent batches every time, reducing waste by 15%.

Another game-changer? Hybrid designs that combine tumbling with gentle agitation for tricky materials. For instance, adding internal baffles enhances flow for sticky powders without aggressive shearing. In pharmaceuticals, this means preserving active ingredients’ integrity. Pro advice: pair it with vacuum capabilities to de-aerate mixes, eliminating bubbles in products like ointments.

Sustainability is huge now, and new models feature energy-efficient motors and recyclable components. Our eco-focused variants use inverter drives to optimize power draw based on load, slashing utility bills. Safety innovations, like auto-shutdown sensors for imbalances, keep your team protected too.

Looking ahead, IoT integration is emerging—remote monitoring via apps lets you track performance from anywhere. We’ve tested this on prototypes, catching issues early and minimizing downtime. For businesses scaling up, these advancements mean faster ROI through reliability and adaptability.

If you’re intrigued by these updates, consider how they fit your needs. A chemical supplier we work with upgraded and boosted productivity overnight. Let’s connect if you want specifics—our long history means we know what works in the real world.