In industries where time, safety, and precision matter, how you move materials can define your success. For companies handling powders, granules, or other bulk solids, electric vacuum feeders offer a smart, efficient solution. Whether you’re in manufacturing, food production, or chemicals, understanding this technology could transform your operations. Let’s dive into what makes these systems tick, why they’re worth your attention, and where they’re headed.

What Are Electric Vacuum Feeders?

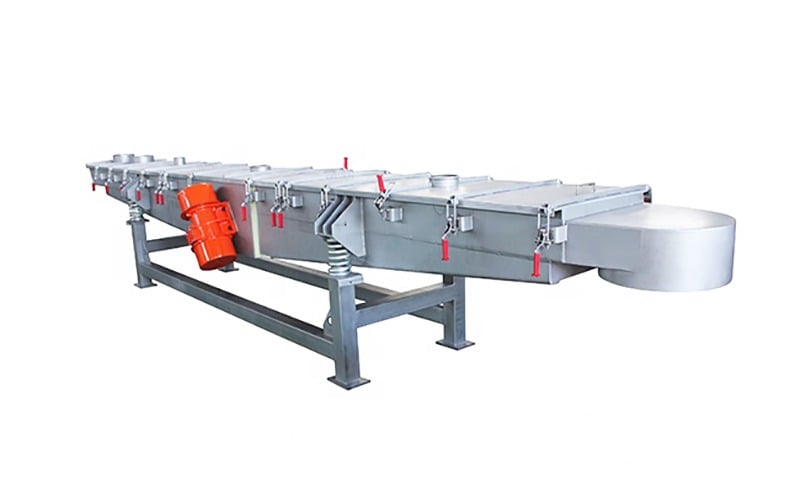

At their core, electric vacuum feeders are material handling tools that use suction to move bulk solids from point A to point B. Powered by an electric motor, they generate a vacuum that pulls materials through pipes or hoses into a collection unit. Once there, the materials drop into whatever comes next—think hoppers, blenders, or packing lines.

Unlike older methods like manual scooping or belt conveyors, this pneumatic conveying approach keeps things contained and smooth. It’s less about brute force and more about clever engineering—perfect for businesses aiming to modernize.

Why They’re a Big Deal: Top Advantages

So, why are companies raving about these systems? Here’s what you stand to gain:

Spotless Workspaces: The sealed design cuts down on dust and spills. For industries like pharmaceuticals, where contamination isn’t an option, this is a lifesaver.

Safer Teams: Less hands-on work means fewer risks. Your crew stays out of harm’s way, and you dodge costly accidents.

Faster Flow: Materials zip through the system, slashing wait times and keeping production humming.

Flexibility: From lightweight powders to chunky granules, these feeders adapt to whatever you throw at them.

Picture a food processor swapping out clunky conveyors for a vacuum feeder. Suddenly, flour stays where it belongs, cleanup shrinks, and output jumps 25%. That’s real-world impact.

Picking the Perfect Feeder: Tips That Matter

Choosing the right electric vacuum feeder isn’t a one-size-fits-all deal. Here’s what to weigh:

What You’re Moving: Sticky powders need different specs than gritty pellets. Match the feeder to your materials.

How Far It’s Going: Short runs are simple, but longer hauls might call for extra power.

How Much, How Fast: Check the feeder’s capacity against your daily needs—don’t get bottlenecked.

Your Setup: Tight on space? Look for compact models that still pack a punch.

Nail these details, and you’ll have a system that fits like a glove—no guesswork required.

Where the Industry’s Headed

The material handling game is changing, and electric vacuum feeders are right in the mix. Keep an eye on these shifts:

Smart Tech: With automation on the rise, feeders are syncing up with sensors and controls for seamless operation.

Green Gains: Energy-saving designs are popping up, trimming power bills and eco-impact alike.

Tailored Tools: Suppliers are crafting feeders for specific jobs—think dust-proof setups for sensitive sectors.

Staying ahead means leaning into these trends. A feeder today isn’t just a tool; it’s a step toward tomorrow’s factory.

Ready to Upgrade?

If your business deals with bulk materials, an electric vacuum feeder could be the edge you need. It’s about cutting costs, boosting safety, and keeping up with demand—all without breaking a sweat. Not sure where to start? Reach out to a supplier who gets your industry. A quick chat could spark some big wins.