Meta Description:

Discover how a hanging vibrating feeder can streamline your material handling, improve throughput, and reduce maintenance costs. Learn essential features, applications, and future trends to make an informed choice.

Introduction

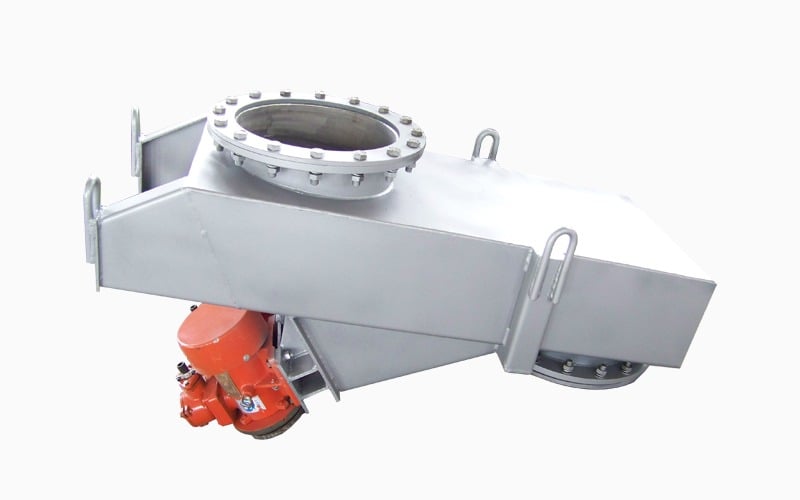

In today’s fast-paced industrial landscape, efficient material handling isn’t just a convenience—it’s a necessity. The hanging vibrating feeder (also known as a vibratory feeder) is a robust solution designed to transport bulk materials smoothly and reliably from hoppers or bins to processing lines. Unlike traditional belt or screw feeders, hanging vibrating feeders use controlled vibration to move materials, avoiding blockages, reducing noise, and minimizing wear.

This article cuts through the jargon to explain:

How hanging vibrating feeders work

Key benefits for B2B operations

Typical applications across industries

Emerging industry trends shaping the next generation

Practical tips for selection, installation, and maintenance

By the end, you’ll have concrete insights to improve your process flow, enhance uptime, and stay ahead of competitors.

1. How Does a Hanging Vibrating Feeder Work?

At its core, a hanging vibrating feeder consists of a tray or trough suspended by springs and driven by an electromagnetic or mechanical vibrator. When energized, the vibrator sends rapid, low-amplitude vibrations through the tray, propelling bulk solids along a linear path:

Material Introduction: Bulk solids enter the feeder from a hopper or silo.

Vibratory Drive: The vibrator imparts vertical and horizontal motion, creating a “walking” effect.

Controlled Discharge: Flow rates adjust by varying vibration intensity or using a mechanical gate.

This simple yet effective mechanism ensures gentle handling of fragile materials, precise feed rates, and minimal dust generation.

2. Key Benefits of Hanging Vibrating Feeders

Uniform Feeding

Vibration yields a consistent, laminar flow—critical for accurate batching and weighing.Low Maintenance

Fewer moving parts than screw or belt systems translate to reduced downtime and lower lifecycle costs.Energy Efficiency

Electromagnetic drives only consume power when active, and the vibration amplitude can be tuned to process requirements.Compact Footprint

Hanging installation saves floor space, ideal for crowded plant layouts or retrofit projects.Gentle Material Handling

Minimal shear and impact preserve the integrity of fragile or abrasive materials.

3. Common Applications

Mining & Minerals: Feeding crushers, screens, and conveyors with ores, aggregates, and sand.

Food Processing: Conveying grains, powders, and snacks without damaging delicate products.

Pharmaceuticals & Chemicals: Metering active ingredients with high precision.

Recycling & Waste Management: Sorting crushed glass, plastics, and metal granules.

Foundries & Ceramics: Handling raw clay, sand, and refractory materials.

4. Industry Trends & Future Outlook

Digitalization & Smart Control

The next wave of vibrating feeders integrates sensors, IoT connectivity, and AI-driven control systems. Real-time monitoring of feed rates, vibration intensity, and material characteristics will allow predictive maintenance and adaptive performance tuning.Sustainability & Energy Saving

As energy costs climb and regulations tighten, manufacturers are optimizing vibratory drive designs, employing regenerative drives, and recycling vibrational energy to lower carbon footprints.

Material-Specific Customization

Advances in simulation software enable precise design of tray geometries and vibration profiles for exotic or sensitive materials—ranging from ultra-fine powders to large, irregular chunks.

Modular Design & Quick Changeover

To meet demands for rapid production shifts, new feeders offer tool-free tray swaps and adjustable spring assemblies, reducing downtime between product runs.

5. Choosing the Right Hanging Vibrating Feeder

When evaluating feeders, consider the following factors:

| Factor | Considerations |

|---|---|

| Material Characteristics | Bulk density, particle size, abrasiveness |

| Required Capacity | Tons per hour or cubic meters per hour |

| Feed Rate Accuracy | Tolerance levels for batching or blending |

| Environmental Conditions | Temperature extremes, dust, moisture |

| Drive Type | Electromagnetic (precise control) vs. mechanical (robust) |

| Installation Constraints | Available headroom, suspension points, floor loading |

Always request performance curves, sample tests, or on-site trials to validate your selection.

6. Installation & Maintenance Tips

Suspension System: Use correctly rated springs or flexible hangers to isolate vibration and protect the building structure.

Alignment: Ensure the tray is level and centered beneath the hopper to avoid uneven wear.

Drive Tuning: Adjust vibration amplitude and frequency to match material flow characteristics—over-vibration can cause material degradation.

Routine Inspection: Check springs, bolts, and drive components monthly; inspect electrical connections and insulation.

Spare Parts Availability: Maintain a small stock of critical spares (springs, liners, coils) to minimize downtime.