For industrial operations, moving materials smoothly and cost-effectively is a daily challenge. Enter hanging vibrating feeders, a smart solution that’s redefining how businesses handle bulk materials. With a design that saves space and boosts reliability, these feeders are becoming a go-to for industries worldwide. Whether you’re managing a tight production floor or looking to modernize your setup, this guide will walk you through what these feeders offer, their benefits, and the trends shaping their future.

What Is a Hanging Vibrating Feeder?

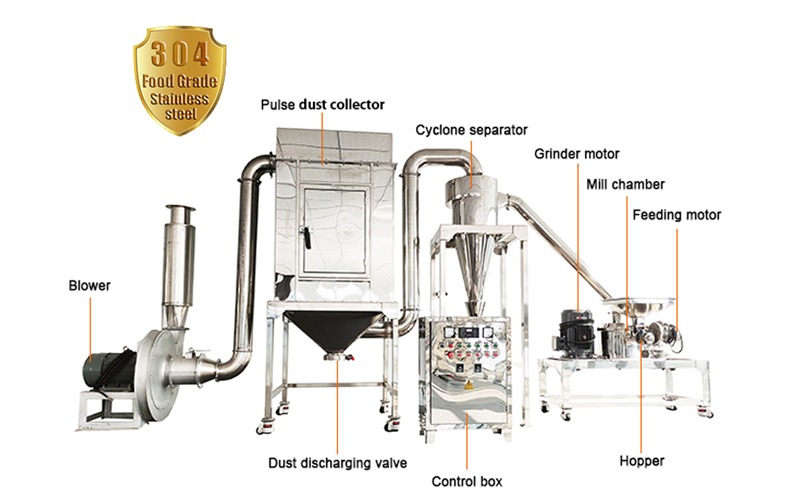

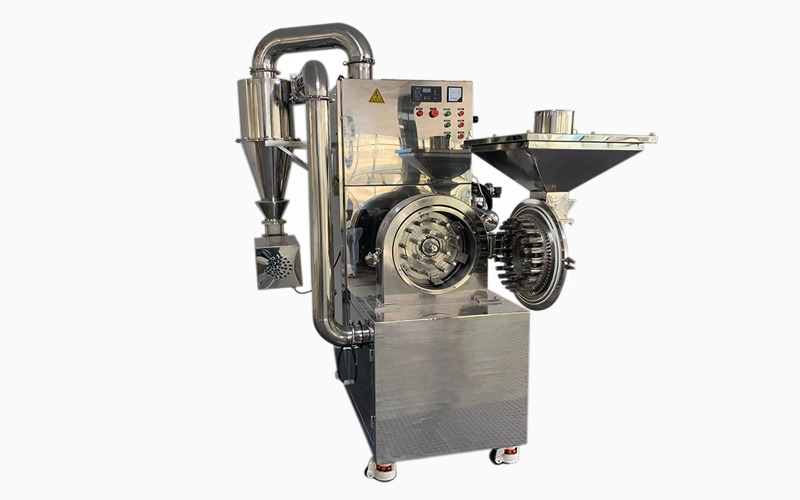

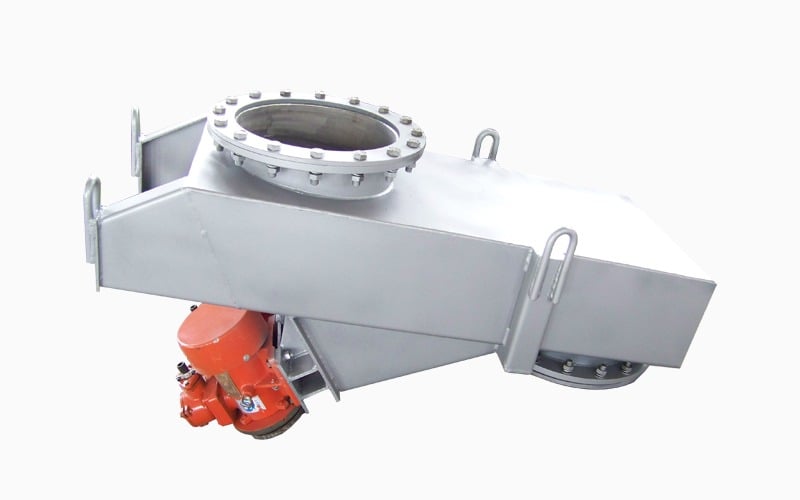

A hanging vibrating feeder is a material handling device suspended from overhead structures, like beams or frames, using cables or supports. It relies on controlled vibrations—generated by an electric motor or electromagnetic drive—to move materials along a trough. From fine powders to coarse aggregates, it delivers a steady, adjustable flow to downstream equipment like conveyors or processors.

The suspended design sets it apart from ground-based feeders, making it ideal for facilities where floor space is at a premium or where elevated material transfer is needed. It’s a practical, no-nonsense tool for keeping operations flowing.

Why They’re a Smart Choice

Hanging vibrating feeders bring a range of advantages that make them stand out:

Space Optimization: By suspending overhead, they free up valuable floor space for other machinery or storage.

Reduced Maintenance: Fewer contact points with the ground mean less wear, translating to lower repair costs and downtime.

Material Flexibility: They handle everything from sticky chemicals to grainy materials, with customizable vibration settings.

Minimal Disruption: The suspended setup cuts down on noise and structural vibrations, creating a quieter workplace.

Imagine a factory where floor clutter slows down workflows. A hanging feeder keeps the ground clear, feeds materials precisely, and cuts maintenance time—a win for any busy operation.

Key Applications Across Industries

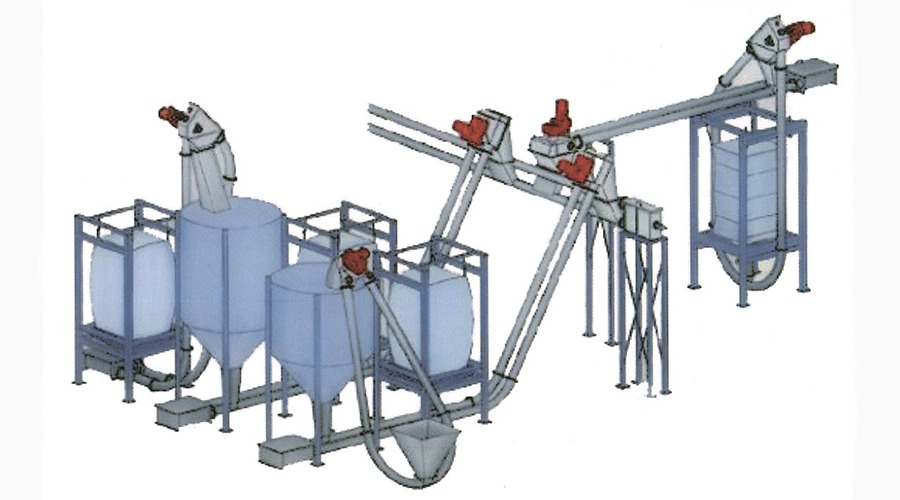

These feeders are proving their versatility in various sectors:

Mining and Quarrying: Delivering steady streams of ore or gravel to crushers, ensuring uninterrupted production.

Food Processing: Gently moving ingredients like sugar or nuts, preserving quality and hygiene.

Pharmaceuticals: Feeding powders into mixing units with precision to meet strict standards.

Recycling: Guiding sorted materials like plastics or metals into processing equipment.

For example, a European food plant recently reported a 20% efficiency gain after installing a hanging feeder to handle dried herbs, reducing product loss and cleanup needs. It’s real-world proof of their impact.

Choosing the Right Feeder

Selecting the best hanging vibrating feeder requires a few key considerations:

Material Characteristics: Assess whether your materials are fine, coarse, or abrasive to choose the right trough and vibration strength.

Production Goals: Ensure the feeder’s capacity matches your throughput needs to avoid bottlenecks.

Installation Space: Verify ceiling strength and clearance for safe, effective mounting.

Durability Needs: For harsh environments, opt for materials like stainless steel to resist corrosion.

A quick chat with a supplier can help you nail these details, ensuring a system that fits your operation like a glove.

Trends Driving the Future

The bulk material handling industry is evolving, and hanging vibrating feeders are keeping pace:

Automation Advances: Smart controls and IoT integration enable real-time monitoring and adjustments, boosting precision.

Energy Efficiency: Newer models use less power, aligning with sustainability goals and cutting operational costs.

Tailored Designs: Manufacturers are offering custom troughs and vibration patterns for specific industry needs.

As industries push for greener, smarter solutions, these feeders are positioned to lead the way in efficient material handling.

Your Next Step

A hanging vibrating feeder isn’t just equipment—it’s a strategic move to streamline your workflow, save space, and cut costs. Whether you’re in mining, food production, or recycling, it can make a tangible difference. Ready to explore? Connect with a trusted supplier to find a feeder tailored to your needs. In today’s competitive market, this could be the upgrade that sets your operation apart.